September 01, 2018

"My devices are good, there maybe noise on channel, cannot help" .... Really ?

in

Snap forward to recent times. A Utility that had issues on certain installation location, was gradually reaching conclusion that PLC technology is too sensitive to noise. The problem description stated that devices installed at a certain location were not reachable for several hours during the day. This hampered the energy efficiency vision of instrumenting energy flow in grid with an acceptable granularity of time. We were invited to perform measurements and confirm the hypothesis.

nBox-Tool was installed at the problem location and left onsite for a week to collect data. A reasonable sized PLC network that is operational with regular readings from end-points (Meters) could generate large amount of data. At the end of the week, we had more than 1 GB logs of data to sift through (yes, 1GB is < 10% of storage capacity of nBox-Tool, and it comprises capture of all protocol transactions over the week at installation location).

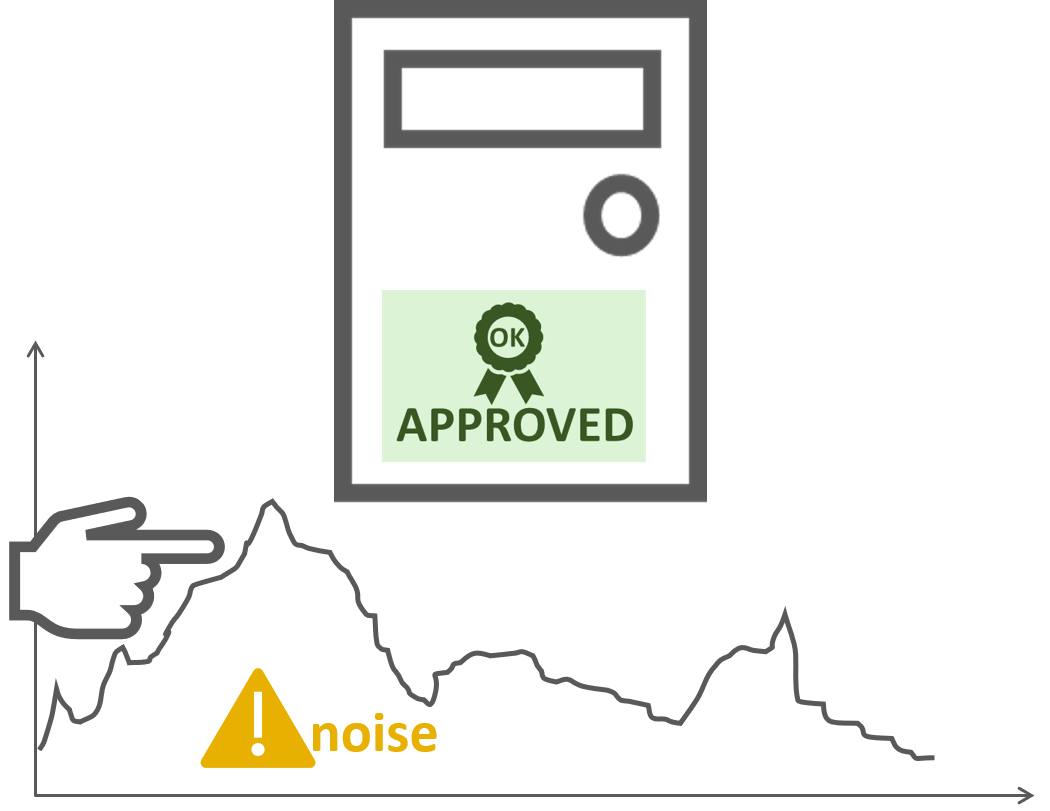

As expected, there was time-specific-noise but not too high to completely block communication. Processing the data, we could conclusively prove that day-after-day, at the time of occurance of noise, the PLC stack implementation was not adapting its modulation schemes to conditions and therefore end-point Meters were unreachable, giving an impression that noise was too high for PLC to operate. The week long data collection with repeat patterns went on to prove a clear implementation issue.

Moreover, analyzing DLMS traffic, the tool also pointed a system configuration mistake, leading to excess data being redundantly polled from meters

Leaving the device on-site for longer duration together with the ability to capture every transmit byte ... does reveal interesting patterns !!

Another location, different Utility, different time and different vendor implementation was plagued by puzzling drop of a certain section of network. Sifting through packet captures and running them through our analyzer scripts revealed that intermediate routing points do not follow the prescribed behavior under certain conditions. Once again, the ability to capture every protocol byte over longer time showed repeated similar behavior, which helped derive definite conclusions.

The one thing common between these two anecdotes is that it is naive to claim protocol and algorithm logic as foolproof. Naive still would be to conclude that packet capture capability is less value than noise capture capability in field environments. We are glad that with engagements like these and with use of nBox-Tool (yes we are encouraging you to buy them !!), we have been able to conclusively prove that PLC technology can overcome mild to moderate noise scenarios ... provided programmers are humble to acknowledge bugs !

In the meantime, the nBox-Tool has evolved to capture noise as well as received signal strength information. The WebGUI also presents it aggregated over longer period of installation times making it one of the trend-setter device that can perform both protocol as well as channel analysis.